What Size Wire For 125 Amp Sub Panel

Stuck on what wire size for 100 amp sub console to use? Does a 100 amp sub panel wire size stand for to a 100 amp wire? Or take you ever wondered what wire size for 100 amp service or what size wire do I need for a 100 amp sub console?

Want to know the short respond? A 100 amp sub panel wiring size requirement is #4 for copper wires and #2 for aluminum wires. Now, you may question what y'all should use for your wiring installation and what are the advantages and disadvantages of one wire blazon from another. Nosotros'll hash out these bug beneath.

Wire Sizes

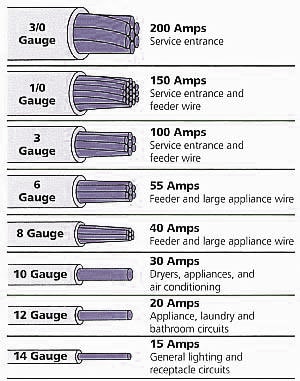

Wiring size requirements differ per amp rating of the circuit. For example, you may use a 10 AWG or American Wire Gauge for a 30 amp appliance, and a size 8 AWG for a 45 amp device. The size of wire you will utilise volition differ also depending on what particular electric installation or servicing you will be doing.

Earlier reading wire sizes, it is important to know the basic technicalities of electric installations. Many newbies or students without feel or avant-garde cognition may miss these easily and crusade serious amercement to appliances and or components.

American Wire Judge is the standard when measuring wire sizes. Gauge simply describes the thickness of the wire through numbers. The smaller the number, the thicker the wire will exist and vice versa.

By that, nosotros tin say that the thicker the wire, the more amperage a wire can support and evangelize. Knowing this aspect or property of wire can save y'all or your appliances from electrical damage, particularly short circuits or even burn down.

Choosing the Right Wire

Depending on your preference, you may choose wires that you think will adjust your project with respect to safety and fire hazard. Most manufacturers put labels on wire coatings or insulation indicating the material's type and estimate.

Most houses use copper wires for wiring installations, including sub-panels and other electric components. Bigger infrastructures, including electrical posts, utilise aluminum wires instead of copper.

Aside from fire safe, infrastructure owners too have into consideration the economical aspect when choosing the right type of materials for their wiring arrangement.

Due to abundance, the apply of aluminum wire, although less conductive, is widely accustomed because it offers a cheaper price, unlike copper wire. Sacrificing a little scrap of efficiency for the purpose of economical proceeds may be a tough telephone call merely a worthy shot.

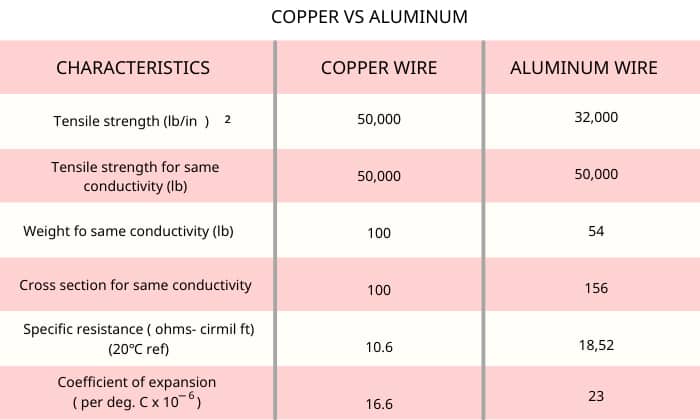

For the purpose of comparison, here are the characteristics of copper and aluminum wires. This may assistance yous make up one's mind what to choose for your sub-console installation and also provide boosted data that you may use for future electrical servicing.

Copper Wire

Copper wires are extensively used in modernistic houses and infrastructures due to the wire'due south smashing conductibility and stability. Its stability and effectiveness in conducting electricity cannot be closely compared to aluminum wires or any other fabric, giving copper the all-time output when talking virtually efficiency in ability, next to silver.

Argent wire is a improve choice in electric conductivity than copper, merely it is not widely used in houses and other buildings or infrastructures due to its disadvantages in other properties, such as a lower melting indicate compared to copper and a higher cost than any other usual conductors we are using.

Although silvery is not that feasible in homes, its use was widely accustomed when it comes to technology. Special wirings and critical components are loaded with silver wires because of the fabric's loftier conductive property.

Another factor why you should consider choosing copper wire instead of aluminum wire is that copper wire possesses loftier tensile force — pregnant it has much higher resistance and protection against breakage. It also expands less at high temperatures compared to aluminum.

One drawback of choosing copper wire instead of aluminum wire is that copper wire somehow is heavier than aluminum when using the aforementioned volume. Copper wire is too costlier than aluminum wires, giving it a prominent disadvantage economically.

Aluminum Wire

If you decided to use aluminum wire for your 100 amp sub panel, you should therefore use #2 aluminum wires to avoid malfunctions such every bit short circuits that may cause electrical harm to your components.

Aluminum wires are way cheaper than copper wires because of the textile's affluence and disadvantages compared to copper wires. It is also lightweight, making it much lighter compared to copper.

Looking on the negative side, aluminum wires are inefficient in conducting electricity. It is too malleable but not ductile, and decumbent to galvanic corrosion considering it oxidizes faster than copper. All these aspects, among others, make aluminum less desirable in residential buildings.

Electrical malfunctions come after human errors and from the usage of inappropriate wire sizes, materials, and substandard components. Moreover, opting for safer and more efficient materials will significantly contribute to adventure reduction and mitigation.

Burn down Safety

If you are planning on installing or fixing sub-panels and came across a determination where you have to choose whether to use copper or aluminum wires, these are the things you should consider.

- Copper is generally safer to apply in electrical installations such as sub-panels because compared to aluminum, copper does non expand easily like aluminum wires when electric current runs through the wires.

- The conductive property of copper makes it efficient in transmitting power or current from 1 end to another. Hence, the transmission does not require much energy that can be lost in the process or transformed into a dissimilar grade of energy such equally heat that may pb to a burn.

- Materials you buy, may it be copper or aluminum wire, should pass the standard set along past your government. This volition requite you enough conviction that y'all are get-go your project on the right path.

Because all condom precautions, it is likewise best to know what you are really doing and the things you are virtually to deal with. Aside from fire rubber, your physiological safety should be the top priority. In other words, before doing whatsoever electrical installations, you should be attentive to things similar:

- If you are not fix to do it, exercise not force yourself to do information technology.

- Equip yourself with more knowledge earlier engaging in these kinds of jobs.

- Gain experience and guidance from experienced individuals regarding the servicing you are nigh to do.

- Call a professional person electrician to do the job for y'all.

Decision

Hopefully, you can at present answer the question "what size wire do I demand for a 100 amp sub console?"

Aside from that noesis, know what precautions to have when installing or servicing your sub-panels or any other type of electrical components.

If you happen to be afraid of risking electric amercement, keep in listen:

- If y'all are not ready to do information technology, do not force yourself to do information technology.

- Equip yourself with more knowledge before engaging in these kinds of jobs.

- Gain experience and guidance from experienced individuals regarding the servicing you are about to do.

- Call a professional electrician to exercise the task for yous.

What Size Wire For 125 Amp Sub Panel,

Source: https://www.galvinpower.org/size-wire-for-a-100-amp-sub-panel/

Posted by: bainknoted.blogspot.com

0 Response to "What Size Wire For 125 Amp Sub Panel"

Post a Comment